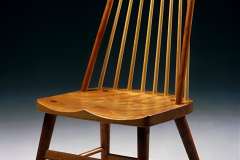

Windsor Chairs, Benches, and Stools

Monday, March 30th, 2020

WINDSOR CHAIRS, BENCHES, and STOOLS: 2019 was the year for Windsor Chair, Bench, and Stool orders. I shipped 14 Contemporary Windsor Side Chairs, 10 Contemporary Windsor Arm Chairs, 3 Contemporary Windsor Benches, 4 Contemporary Windsor Low-back Stools, 3 Contemporary Windsor Low-back Swivel Stools and I took orders for an additional 4 Walnut Contemporary Windsor Side Chairs. I sold another of my Contemporary Windsor Bowback Benches in hickory and finally the Custom Windsor Hall Bench (pictured below in cherry with ash spindles) that is sitting in the shop right now in March of 2020. Eighteen of the chairs were ordered by one decorator from my own state of Vermont, but the rest of the sales came from 7 different clients spread out across the country. Please click on the links above to go to the web-page for that particular item or click on the thumbnails (some are quite distorted) below to see a larger (properly proportioned) picture. Click on this link for a brief description and history of Windsor Chairs. If you click the Arm Chair link above you will see a picture of the other variation of this chair with canted arms. In the photo(s) below you will see the arm chair with arms parallel to the seat.

I have made these benches and chairs in other sizes, woods, and finishes. I’ve made taller, deeper chairs for tall customers. I have made a shorter, deeper bench to accommodate a cushion. I’ve made many different lengths of benches and I have made variations of armchairs to suit the table they need to fit under. Call to order something slightly or completely different: 602-252-1904.

Finally please note that there are two pages of thumbnails; if you scroll down to the bottom of the first page you will see small numbers 1>2 and clicking on the 2 will take you to the second page.